Mark Zalesky, the editor of Knife World has purchased the

paper and is now the editor, publisher, and chief bottle washer. We spoke for a while at the BLADE Show and

he’s quite excited. I think you’re going

to see big changes at Knife World. Good

Luck, Mark!

I was visiting at Spyderco and enjoyed some of the inside

stories about knives and knife makers.

They have just expanded with a new 17,000 square foot manufacturing

area. That means more knives stamped

Golden Colorado, USA Earth on the blade tang.

They are still figuring out the best way to set machines and organize

work flow, but do you know what they’re most excited about? The factory windows can open letting in fresh

spring air, that’s what!

They are reintroducing their line of kitchen knives. While not as nearly as heavy as many

profession knives, they are nicely balanced and sharp. I love their bread knife and the little

paring knife. The large santoku doesn’t

have the little air breaks indentations seen on other santoku. That might just be an advertising ploy, well

have to see how it works.

|

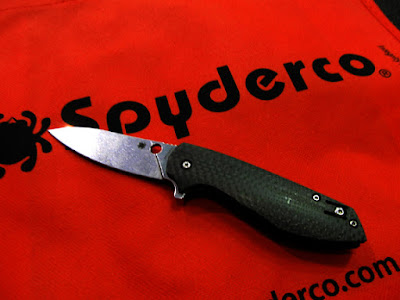

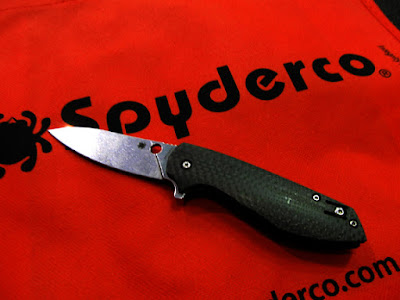

| The Positron. This knife is so cool both my wife and I want one! |

I got to handle their new Positron. It’s a 3-inch flipper blade made out of S30V

in a carbon fiber handle. It weighs 2.6

ounces. It’s lovely!!!

Here’s another knife from Phil Wilson and Spyderco. It’s called the Sprig and sports a 2.23 inch

blade made from S90V steel.

|

| The Sprig |

It’s a bird and trout fixed blade. The sheath is still under development. While it targets a specific use, it would

make an all purpose camp and cooking knife.

S90V has high chromium levels for corrosion resistance and high vanadium

and molybdenum. These last two elements

form tiny but incredibly hard carbides which should give great edge retention.

Of course Spyderco and everyone else is still plagued with

knock-offs from China. If you have

searched for Spyderco or Benchmade you’ll find that Wal-Mart has them and at

incredible prices. Spyderco tells me

Wal-Mart isn’t getting these knives from them, so who’s wholesaling them? “Lot of counterfeits out there. You get what you pay for.” Take that as a quote!

Stopped by Benchmade to look around. Try and get your hands on the 665 APB

Assist. It’s vey new and quite exciting.

|

| The Benchmade 665APB |

Most of us are familiar with the Benchmade Axis lock. The lock is thought to be one of the

strongest and certainly easiest to use on the market. The APB Assist does away with the axis lock

and replaces it with a dual button lock.

The person I spoke to at Benchmade told me it was just about as strong

as the Axis lock. I haven’t used the

knife yet, but I can’t help but wonder if my grip would accidently depress both

buttons.

|

| The two buttone must be preseed together to unlock the knife. It's very smaooth and a natural move. |

The knife opens normally but to close it you pinch both buttons

inward and that unlocks the blade. Very

slick. The 3.6 inch blade is made from

154CM steel and the blue and black handle is very nice. Benchmade told me they were trying to

introduce a color in to the overwhelmingly black tactical market. The APB Assist also comes in a full auto version

(6800 Auto APB Assist). The catalog

shows it black, but the version I saw was blue and black with the same

handle. I suspect it was a quick production

so it was available for the show.

Benchmade is making several other autos aimed at the

civilian market with clean powerful lines.

Several don’t even look like autos.

The auto APB Assist an excellent case in point.

Benchmade also has this cool service at the Blade Show. They will engrave any Benchmade knife blade

with any text. The laser engraver isn’t

much bigger than a couple shoe boxes cabled to a laptop computer. The text is typed in, moved around and

sized.

|

I remember when engraving lasers were the size

of a small auto! |

.

Spelling is checked and you

can see the size and position of your text outlined in red laser light

When everything is set up they close the doors and punch

go. A bright green spot of light burns

the text into your blade.

|

| Now you can personalize your Benchmade for the cost of a trip to the Blade Show! |

If you are going to Blade, take your Benchmades and get them

engraved!

I stopped at Buck and found myself talking with CJ

Buck. At the WRCA knife expo I bought a

nice new Buck 110 Hunter with what I was told were stainless steel

bolsters. Having a Buck for years, it

soon became apparent the brass bolsters react with the fatty acids in the

leather to produce a green corrosion. I

was wondering why Buck stopped make 110’s with the stainless steel. CJ told me they never made a steel

bolster. That would require machining

which would drive the price up.

What I

have is German Silver, a mixture of 60% copper, 20% nickel and 20% zinc. It turns out that brass and German silver have

about the same melting point so the same casting equipment can be used for both.

No Blade Show is complete without a stop at Santa Fe Stoneworks. It only takes one look to be convinced to

stop and ooh and ahh. Truly impressive

knives.

|

| A small selection of the knives |

I’ve see this knife-making display before. Knife-making made simple.

|

| See! Five Steps! |

So what’s stopping us?

I’m walking around and I see a name I thought I recognized

from a knife blog I read. She’s an elderly

lady standing behind a counter talking to a customer. In front of the counter stood a short, silver

haired woman talking to a distinguished looking elderly man. I was waiting for the customer to leave the counter when the silver haired woman turns to me and says:

“How are you? It’s so

nice to see you again!” She throws her arms around me and gives me a hug. I don’t know this woman. The conversation goes:

Me: “Thank you but I don’t seem to remember your name?”

Her: “Oh, you were drunk that night.”

I haven’t been drunk since high school

graduation, so if I met her then, she has a remarkable memory. What am I going to say to her? Oh, I got it.

Me: “Perhaps you're right, would you please tell me you name again.”

She does and I’m still not coming up with any connections.

Me: “I’m afraid I

don’t recognize what name.”

Her: Do you know Blackie Collins?”

That when the ants started marching up and down my spine dragging

ice cubes.

Me: “Well, of course I know of him, but I also met him years

ago at the SHOT Show. He was very kind

to my wife and myself. A gracious

man. He unrolled these large scale

drawing of one of his new knives and showed us how it worked and what the

interesting design features were.” I ran

out of things to say, so I ended with ”He was very nice to us.”

Her: ‘I’m his widow.”

Oh! Well what else

can you say other than “You have my deepest condolences.”

We yakked a bit and I excused myself only to find out the

woman behind the counter wasn’t the blogger I thought she was.

Here’s a few additional photos from Blade 2015:

|

| Grinding Demo by John Horrigan Too many people to get a nice shot of the actual grind |

|

| The art of Chris Reeve's knives! |