There are few knives better known

in the knife community than Spyderco’s Endura and Delica. Introduced in 1990, they have always been in

the top ten sellers at Spyderco. But there is a new contender, the Endela.

|

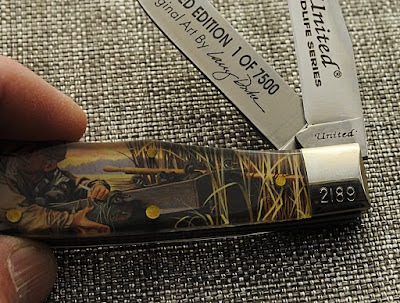

| A full serrated Endela flanked by a Delica and Endura. |

Spyderco’s Delica was the first

tactical knife I ever owned. I owned lock

backs prior to a Delica, but never one with a clip or engineered for one-hand

opening. The ability to consistently

open a knife with one hand which would lock open was amazing. From camping to community theater, in fact

any daily activity, these knives made an impact.

Police, fire and military all tended

to carry an Endura or Delica. They were

strong, lightweight (compared to the other popular “tactical carry“ knife of

the time, the Buck 110), easy to open and economical. The steel retained its edge reasonably well

and could be quickly sharpened with the Spyderco Sharpmaker, which I still use. Both knives still retain the properties of

strength, ease of operation and performance.

Long before 9/11 Delicas quickly

found a home with airline travelers. You

simply dropped them in the tray with your car keys and pen, and they were

returned on the other side of the metal detector almost always without a comment.

Even the partial serrations were not of

any real concern. I typically carried

two while my wife carried her Delica. I

use to sit in mid-flight and cut open my in-flight snack. That makes me feel nostalgic.

As a purveyor of edged steel, I am

more than qualified to state the obvious:

No matter how well designed, no knife or series of knives is perfect for

all users. One only has to look at all

the available glove sizes to realize that.

The Delica and Endura are the Baby

and Papa Bear that drunk blonde, Goldie, finds when she breaks in to a fairytale

home in the woods. So what fills that

middle spot? Consumers asked for a

bigger knife that was smaller than the Endura.

Spyderco found an answer, the Endela.

|

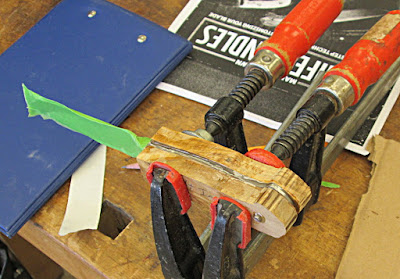

| Daily lab chores, opening packages. The blade was very controllable. |

Let’s do a three way head-to-head

with the new addition to this family of edges, the Endela.

|

Feature

|

Delica

|

Endela

|

Endura

|

|

Open length (inches)

|

7.13

|

8.1

|

8.8

|

|

Blade length (inches)

|

2.88

|

3.4

|

3.8

|

|

Blade thickness (inches)

|

0.09

|

0.12

|

0.13

|

|

Steel

|

VG-10

|

VG-10

|

VG-10

|

|

Grind

|

Saber

|

Flat

|

Saber

|

|

Clip

|

4-position

|

4- position

|

4-position

|

|

Weight

|

2.5 oz.

|

3.1 oz.

|

3.6oz

|

|

Cost (MSRP)

|

$120.00

|

$123.00

|

$125.00

|

As you can see, the Endela looks a

little like the middle child. The blade is

about a half inch larger compared to the Delica, but 0.4 inches smaller that

the Endura. Blade thickness is pumped up

by 0.03 of an inch, but its 0.01 inch thinner than the Endura. You’ll see that trend in the other knife

parameters too. The Endela is a

noticeable step up from the Delica, but almost a twin to the Endura.

Frankly, the Endela seems to be an

answer in search of a question.

The Endela comes only as the flat

grind blade, which seems to be super-hot on with consumers right now. Both the Delica and Endure can be found with similar

flat grinds. Both the Endura and Delica can

be obtained with a plain edge, a partial serration and full serration. The Endela sports either a plain edge or a

full serration.

The full serration has amazing

cutting powers. Packing straps, seat

belts, heavy rope all come clean to its power.

The little defensive edge training I have taken strongly suggests I

don’t want to be cut by a Spyderco serration.

The Endela market, according to Spyderco,

is for those of us who want a larger knife than a Delica, but smaller than an

Endura. Hence the mash-up. Not the most original, but…..

The difference is in the feel and

use. I like the Endela. It feels good in my hand and if I was a first

time buyer, I’d get an Endela.

It will

be interesting to see if it’s in the 2021 catalog.