I ran in to a young man who is just starting to make knives. For the last two years he’s hammered, removed stock, taken classes, sharpened edges and dropped a lot of sweat on the ground. Why? Because David Pienta wants to be a master knife maker. But the road is long and twisty and not everyone makes it, but he’s starting. Right now he’s working with stainless Damascus steel he hammer forges himself.

I bought the one on the bottom

The name of his forge? Fenic Forge. The name derives from the chemical symbols for iron, nickel and carbon, important elements in steel. He doesn’t have a tang stamp yet and I urged him to. Many of his knives are objet d'art and without a tang stamp their value will be less. I’ve handled too many nice knives that everyone simply shrugged and said “Beats me who made it or what it is worth?”

|

| Bold Tiger Stripe Damascus |

We disagreed on the artistic nature of his stainless Damascus choppers. He thinks they are practical Choppers. Perhaps. I think you will not see too many Damascus knives as choppers. Yes, I know the maker has the edge on what he thinks his knives are for, but it is really up to the consumer.

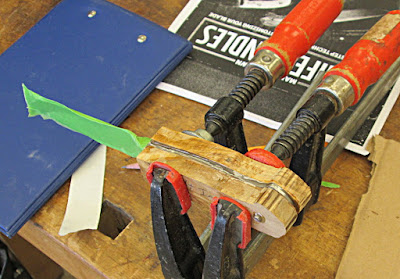

I bought a small kitchen utility

knife, maybe seven layers of steel in an exotic burl handle. The handle has

good symmetry and the blade has nice lines for a small working knife. The small number of layers allows the differences

in steel to be bold statements. The working

edge ends with a gap between the steel blade and the handle. I like the way my finger sits in that place,

so clearly defined with no worries of sliding onto the blade.

|

| My kitchen utility knife |

I’m going to sharpen it bit more and treat the handle to a good wax coating and Karen will have a special kitchen knife.

You can find David on Instagram

or http://fenicforge.com/.