Making a knife doesn’t mean you have to start with a lawn

mower blade and a forge. A variety of

steels in terms of grade and types are available. Also available are knife kits which in which

the blade is pre-shaped and

sharpened. These kits also come in a variety

of completion. Some have all the

components and you assemble your knife. Other require a little more effort on

your part.

Woodcraft offers a variety of learning projects so I signed

up for the knife making. I wanted to see

how they handled epoxying and pinning handles.

As you’ve seen on Forged In Fire, pinning handles onto your knife is one

of the major stumbling blocks for contestants.

They need to drill through steel, align holes, hammer pin in place while

the five minute epoxy is hardening.

|

| Basic kit plus wood handles |

Here’s my kit and I’m using a light olive wood for the

handle. The first step is to turn a 3/8

inch thick slab into two slabs. The

second is to tape your blade with removable painters tape. Use lots of tape to protect your hands from

the edge. Safety first.

|

| Turning one piece of wood into two |

We traced the handle on the wood blanks making sure a square

end of the wood are in complete contact

with the bolster, then on to the band saw.

Removing excess wood is a time saver, but leave enough just in case your

handle needs to be finessed a little. But

really, a hand coping saw would have worked just as well. You could just sand it all away too.

|

| Taped, trimmed, ready for epoxy |

After you assure yourself each side of the knife’s handle

has the correct cutout, the pins fit correctly and you’re happy with everything,

dry fit it together again. Can’t be too careful!

|

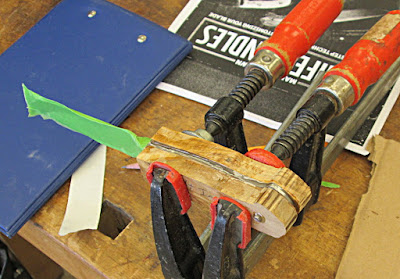

| Clamped |

Now get the clamps out and mix your epoxy. So, Bunkie, five or thirty minute epoxy? The class used five minute because it is fast

and we gave it a half hour. I like the thirty

minute or longer. I want the longer time

for fixing an “Oops!” and I believe longer cure epoxy is stronger. While I have no plan to destroy an elk’s

skull or batter the hood of a 1948 Ford pick-up truck with my knife, stronger

always seems better to me.

After the epoxy is cured, it is sanding time. Woodcraft has a variety of terrific sanders,

rotary oscillators with different radius, belt sanders, disk sanders but all

you really need is any sander you have and patience.

|

| Sanding in process. |

Your plan of attack is different from anyone else. I like a rounded handle with a palm swell and

flat top. Start removing wood, but

remember the Golden Rule of carpentry:

It’s easy to take wood off, very hard to put wood back.

Keep handling your knife.

How does it feel to you? Too thick? Too rough?

Edges sticking up? Keep

working. And while you’re striving to

make your knife, remember perfection is the enemy of accomplishment. Experiment with it. Do you want an asymmetric “D” shape handle or

maybe oval facets?

|

| Finished |

When you get it to the shape you want, move to a finer grit

paper. Work your way down to a finish

you want. How about polishing to a 4000

grit finish? The wood starts to come

alive the more sanding dust you create.

The wood finally explodes to life with a finish. You can stain it, wax it, linseed oil it,

urethane it. That’s up to you. I used a coating of flax seed oil. Just a fancy name for linseed. That a drying oil, so I left it outside in

the sun to help cross link the finish.

|

| Just one variety of the steel and blade shapes available |

It’s not perfect, but the next one I make will be

better. I know what to look for and what

to watch for. And I know how much fun it

was.