One of the interesting factoids from the Blade Show is

Emerson Knife is a small company. They

have only a handful of employees. I find

this surprising. I’ve always assumed

(there’s that word) that Emerson was a large company. Of course, large and small are vague terms at

best and can be quite meaningless.

This explains the disclaimers seen in catalogs “Due to high

quality standards, Emerson produces a limited number of knives per year…” I suspect it isn’t because of Emerson’s

excellent quality that limited numbers are available. It’s because the physical limitations of the

company limit the number of knives manufactured.

In an effort to promote the Emerson brand outside of knife

circles, Ernie has sold several of his designs incorporating the quick opening

‘wave’ to Kershaw.

I stopped at the Emerson booth and asked if this was a sort

of collaboration between Kershaw and Emerson.

That brought people to their feet quickly. I’m just glad there was a counter between us.

“No!” I was told.

“Those designs were bought by Kershaw, will be manufactured by Kershaw,

marketed by Kershaw, and all warranty work will be handled by Kershaw.” If there was a sink present he would have

washed his hands.

I was told Ernie wants more name recognition in the general

public and Kershaw will be selling these through Wal-Mart and other

mega-stores. I found them in Kershaw’s

2014 catalog as the Kershaw-Emerson knife.

Their SKU will be the familiar CQC-1 through 8 followed by a K.

A couple weeks ago I had a chance to handle one. I thought it was stiff to open. The blade was made from 410 steel instead of

154CM and in general, it’s a smaller knife.

The price difference could be as much as $230 retail. I suspect they will be made in China.

Frankly, I never really trust Wal-Mart. Too many past stories of them selling junk

and damaging companies and communities.

The Rubbermaid story is a cautionary tale.

It’s like Emerson is making their own counterfeits.

Counterfeits are a big problem in the knife world. The Chinese are making counterfeits that are virtually

perfect down to the printing of the product insert.

I went to one website that sells (no, I'm not telling) knock-offs. They had a fixed blade, with a leather sheath

that looked just like a Randall knife.

The image was low quality, on purpose I suspect, but it looked like the

metal snap on the retaining strap said Randall.

If you want to buy more than 30, you can get them for under

$100 each. Each one could be sold at a

gun or knife show for over $500. Since

many of these will end up in a drawer or display case it’s almost a victimless

crime, right?

Except for the fraud, except for the person who buys it and

uses it, right? When it fails and at

best it will give diminished performance, who’s going get the bad rap?

It can also happen accidently. The seller sells it as a knock-off, but by

the time it gets to the third or fourth buyer that fact is misplaced. Randall is not the only one sniped at. Spyderco, Benchmade, Emerson, CRKT, Gerber

and the rest, they’re all being knocked off.

Customs doesn’t seem to care. They come right through. I spoke to a fellow whose knife was ripped

off. Sure, he could take the case to the

Chinese courts. Spend a lot of money, do

battle for several years and in the end the courts might say, “You win. Now tell us how many knives you didn’t sell

because of the knock-off so we can assess damage. Was it 10, or 1000 and

where’s your documentation?”

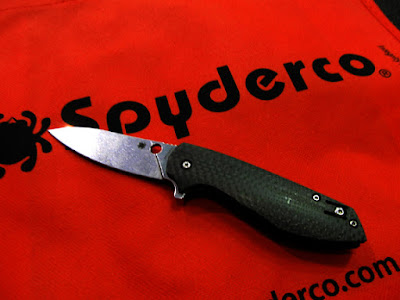

The Blade Show had a display of knock-off Spydercos, among

others. Only by holding them side by

side could I tell the difference between the marked counterfeit and the real

deal. The counterfeit spider on the clip

was more like a spider, the real mark looks more like a tick.

|

| Can you tell which is real? The bottom one is counterfeit. |

I’ve had people come up to me and tell me that brand X is no

damn good. They had one and it

broke. I ask what they paid and who they

bought it from. The answer is typically

30 bucks from a guy standing outside the show with a box of them. "Oh," I say. "You paid 30 bucks for a $180 knife from some guy who didn’t want to

pay to get into a gun show and you’re surprised it broke?"

“Well,” they sniff. “I thought I was getting a really good

deal.” Do me and yourself a favor. Check out the retail prices on websites and

if some website or guy in a hoodie wants to sell it at 60% below retail, you

should know it’s a counterfeit.

I also had a chance to talk to a future knife designer. He’s there with a protoype of a folder with a

blade bigger than the handle. He uses

the clip to protect the end of the folded blade extending out of its

handle.

|

| A truly large bladed folder |

What seems to be unique to this knife is the clip is spring

loaded so it snaps down the back of the folder’s handle to give you a normal

size handle when the blade is open.

|

I'm holding the knife by its pocket clip. No. I'm not putting that in my pocket!

|

|

| Here's the back in the closed position. |

It

reminded me of a high tech Marble’s Safety folder. I wish him well, but (open mouth – insert foot)

it’s a stupid idea. The bigger blade

might be useful, if the pivot will support the load and if you don’t cut a

finger off trying to get it closed.

One wonders if primitive man carried an assembled stone axe

or if he just carried the knapped stone and made the handle and then tied the

stone to the handle when he needed it. I

suspect he carried it already assembled.

And do you know why?

Because when you need an axe, there usually isn’t time to

assemble one.

|

| Add handle and instant axe! Almost. |

I saw a high tech axe head that acts that way. When you need it you first need to cut a

suitable size tree limb. You can use the

sharpened axe head by holding it in your hand and flailing away at a

branch.

|

| Please note the handle isn't a branch. but a manufactured piece of hickory. |

Then you need to cut a groove

down the center of the branch of sufficient width so the axe head can slide

down the middle of the shaft without cracking the shaft. Using clever, claw-like clamps you can

tighten a grip on the branch so the head doesn’t fly off while you’re using

it. Now you’re ready to chop wood.

The inventor wanted to peddle it to the

hiker/camper/survivalist market. All you

need is the axe head, which is light weight and small and you can make an

axe. No reports from anyone who tried to

chop wood with it.

|

| The handle appeared to be cut on a band saw. This would make the perfect gift for that outdoors person you didn't want returning. |

I suspect it will end up in the bottom of a go-bag waiting

for the collapse of civilization. Look,

I could understand if the inventor suggested pre-cutting wood to fit the axe

head. The axe would be easy to pack and

it is lightweight.

But if you need to make shelter NOW! Or need a fire NOW! spending an hour or two making this axe is

going to cost you. I suggest if you

carry one, the first thing you should do when you get lost is stop, get the

head out and start making an axe. Use

that time to calm down, think about your plan, your immediate needs and then

work your plan which now includes cutting wood for fire, snares and shelter.

One thing for sure, the Blade

Show is never dull.