In an effort to get ahead of my summer fitness cycle, I have started walking with a 15 pound backpack. I chose a single sling pack from Maxpedition with my special attachment, one of Boker’s collaborations with Mickey Yurco. It is called The Pocket Knife. The Ulticlip allows you to clip it inside a pocket making it easy to carry and access a fixed blade.

|

| Boker's Pocket Knife on my pack |

|

| The blade isn't quite so long, all due to accidental camera angle magic |

|

| Two knives held in the same position with my wrist at the neutral angle. The Boker extends outward more aggressively |

We are, after all, tool-bearing mammals and a knife is just a tool.

The blade is a graceful saber

grind drop point blade tapering to a point made from 440C stainless steel. It is 3.3 inches long with a 0.15 inch

thickness and the overall length of the knife is 6.8 inches.

The handle is constructed of

black G-10 and has a slight palm swell making it easy to grip. The finger detent in the steel and the palm

swell make gripping this knife easy and comfortable. It is in the running for the easiest and most

comfortable using knife I’ve ever owned.

|

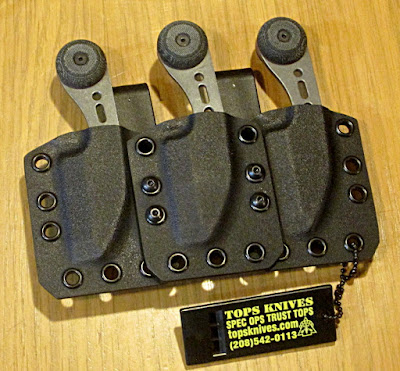

| The Kydex sheath |

The Kydex sheath secures the knife upside down and close to the body. I don’t have to worry about bushes or brambles plucking at my knife in an effort to detach it. The Ulticlip lets me clip the knife on the padded shoulder strap about the middle of my chest. This is just about where a surprise or fear reaction instinctually brings the hands to. The clip allows almost instant removal should I need to move the knife and sheath to a different location.

Why a knife? Because sometimes I can’t get to a firearm

fast enough. If I had a dime for

everyone who told me they would simply draw their blaster and shoot their knife/club

attacker I would be a rich man. While a

subject for a different blog, attacks are usually done by surprise, without

warning, and with a high level of violence.

Awareness is the key to survival, followed by having a tool and skill with

the tool.

|

| The Ulticlip allows you to move the knife and sheath from location to location quickly. |

If you are not familiar with Boker, or only think of the lower spectrum of their knives, think again. Boker makes some very high and middle-level knives at reasonable prices and excellent quality. Mickey has at least two knives in the Boker catalog. I find the Yurco Pocket Knife one of my favorites.