Gerber

Strongarm— that's a hell of a name, isn't it?

But yet I remember strongarm inspection.

Maybe it's not such a great name.

Despite the name,

the Strongarm is a combat knife. First,

let me get this out of the way.

According to the Gerber website, they have made 'survival' knives since

1968. Gerber released the Mark 1 and 2

back around '66 as combat knives, and they were a hit with the military. That is to say, with the boots on the ground. For reasons never explained, Gerber was

stopped from selling these knives in PXs.

Gerber relabeled them as survival knives and PX's welcomed them with

open arms.

|

| The Gerber Strongarm |

Since a survival knife can be defined as the knife you survive with, the Strongarm certainly qualifies. But it is a combat knife.

The blade is

ground from 420GHC steel, a hard martensitic steel. With 12% chromium content, it qualifies as

stainless. Gerber gives the blade what

it calls a ceramic coating for additional protection. Washing off corrosive chemicals and wiping a

blade down with oil never hurts. The

partially serrated blade at 4.8 inches long, is a useful length for many knife

chores.

Gerber describes

the blade as a drop point; it is really a clip point with a false edge. The Strongarm reminds me of a Bowie knife

blade.

|

| I see this as more of a clip point with a false edge |

The full tang

blade is 0.19 inches or 3/16 of an inch thick.

Gerber doesn’t say what the hardness is, but it has been suggested 420HC

steel has a sweet spot for hardness around 56 to 57 RHC.

The handle is shaped to help retain the knife in your hand. The diamond texturing helps

I know. Some of you are only satisfied once a blade reaches such hardness that only a monocrystalline diamond in a tungsten carbide matrix will sharpen it. A general rule is that hard knives are brittle knives, which leads to the truism that a broken knife is junk, while a bent knife is still a knife.

The handle is a

rubberized polymer with a diamond texture and striking pommel. It also sports a guard to keep your fingers

off the blade, a handy feature in working knives.

|

| Get a grip, bunkie! The pommel can be attached to a lanyard. |

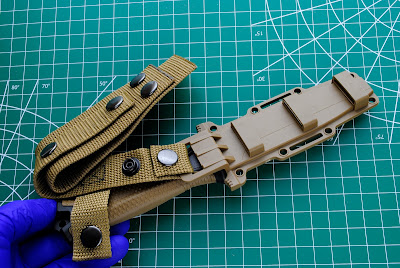

The knife is 9.75 inches long and weighs just over 7 ounces. The sheath is customizable, and Gerber provides adaptors so you can wear the Strongarm on your belt, as a drop leg, on a MOLLE rig, sideways, upside down, or horizontally. The sheath can also be lashed to other items.

|

| The sheath is very adaptable. |

I like this

knife a lot. If I was heading out to

hunt Dal sheep, raft the Amazon, or shipping out to active duty overseas, I'd

take at least one of these with me.

Remember, one is none and a knife-less man is a life-less man.

The knife’s balance

was in the handle behind the guards, where I like it, and the grip felt good in

my hand. The Strongarm clips in very

securely in the sheath. I welcome the

little extra force needed to draw this knife. I want to know my knife isn’t going to fall

out if I take a spill. The polymeric

sheath looks tough enough to prevent the blade from penetrating the sheath and injuring me, another feature I’m crazy about.

|

| The Gerber Strongarm |

Does it

cut? Well, here’s where I must assume

so. It isn't my knife, but it belongs to

a retired military man who wants to set up his daypack the way he carried it

back in the day.

Don't be a foolish. Consider Gerber's Strongarm if you need a

hard-working, EDC fixed blade for harsh environments.

You can find one at https://www.gerbergear.com/en-us/shop/knives/all-knives/strongarm-coyote-brown-serrated-30-001059 for $90.00. It's a good deal for what you get.