The trick or treaters gathered in

homes around Akron and the burgs in preparation for what is a yearly rite of

passage, Halloween. Routes are mapped,

evaluated, altered and re-planned. Last

minute adjustments to costumes and provisions for rain are being made, cancelled

and re-adjusted even as I press my keyboard.

Moms have programmed a route in their GPS. Their SUV will pull up to the driveway, the

door slides open and kids will pour out like an incoming tide.

We too are ready. Two years ago we ran out at 400 pieces and

had to sneak back into the house, turn off the porch light and pretend we

weren’t home. We’re ready this year with

an excessive but undisclosed amount of candy.

Dentists around the city have been sending us thank you notes. Yeah, we have a lot of candy.

|

| Two of my favorite knives: Mickey Yurko and a Russian Fisherman |

It’s also a two pumpkin year for

us. We always make the mistake of buying

the pumpkin and then deciding how to carve it.

Some designs work better than others, but we try to sandwich our last

minute inspiration onto a pumpkin not suited for it almost every year. What the heck, it’s about having fun.

|

| Proto artwork |

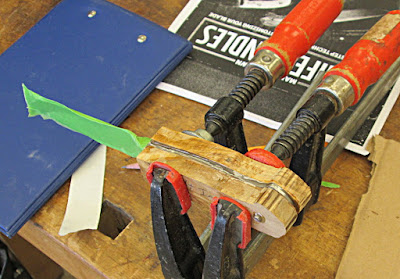

I selected two knives to work

with. I have an orange and black handled

Mickey Yurco in D2 steel. One of the

cool things Mickey does is he gives all his knives a unique number. I have the 3407th knife he has

made. I bought it because of the blade

and the handle. It always reminds me of

Halloween. If a movie monster jumps me

Halloween night, it is in for a bit of a surprise. This knife cuts.

|

| Russian Fisherman style knife, not a flay knife |

The second selection was a

Russian fisherman knife with a stacked wafer birch bark handle. The blade is made from one of the Russian

knife steels. The Russians are doing

some amazing metallography and developing interesting steels. It is very much in the puukko style which has

been interesting me more and more. The

long, simple lines of the blade are elegant.

But it is birch bark handle that attracts me.

Anyone who has carved pumpkins

knows the biggest problem is manipulating the blade. Too much pressure and the blade shoots

through the fleshy pumpkin wall like magic and over shoots the endpoint. Too little and the knife gets the idea that

it is Excalibur stuck in the stone and you’re not King Arthur.

|

| The two best tools |

Look, I have knives. There’s never a shortage of sharp edges around

here, but in truth, do you know what works the best?

The thin bladed Victorinox

kitchen paring knife and a dull, course saw-like blade made for children. The saw gives you the most control shaping

and cutting and paring knife lets you sharpen and open up features to make them

transparent.

I’ve tried a lot of knives for

carving pumpkins. One year I tried to be

edgy with a chainsaw. It took me months

to get the saw cleaned up. Trust me;

you'll be happier with the above recommendation.

I look forward to Halloween all

year. It’s one of the few times I feel

comfortable talking to children I don’t know.

PS: It was rainy, cold, windy and we still had at

least 300 kids.

|

| BOO! |