I inadvertently rubbed that strange brass lamp, and the Genie promised me only one wish, not three. I guess inflation gets everyone. But there is a catch; magic has a price. "The price," the Genie solemnly announced, "is you can only have one automatic knife for the rest of your life."

I can work with that. Here's my choices.

|

| A.O.S. by Les Adams |

Les Adams makes an A.O.S.(Always-On-Safety) automatic knife. He makes the carbon fiber handles himself, and since the knives are actually made for LEO and military use, each one has a unique serial number. It's a well-made knife with a 154CM stainless steel blade with 59-60 Rockwell hardness, C scale. He claims the stainless coil spring has twice the spring force of any auto knife. I believe it. The knife opens with a jump, and the blade locks open with a resounding 'clack.' But you must pull the safety back and hold it in the unlock position while pressing the opening stud. Same for closing. It's cumbersome.

|

| Benchmade Mini-Reflex |

The Benchmade Mini-Reflex has a lot going for itself. The one I have is a pre-production model from 1998. It hasn't changed much since then. The small 3.25-inch flat grind blade is held in an aluminum handle. I was told this one is epoxy-coated, which is something Benchmade stopped very early in production. The knife has a safety on the spine and a recessed area for the release button. The button does extend above the handle. The spring in mine isn't as strong as the A.O.S.. If the blade is stopped after an arc of 90 degrees, the spring doesn't have enough stored energy to open and lock. A flip of the wrist solves that.

|

| Puma Medici Switchblade |

I also have a classic Italian stiletto switchblade made for the German market in the 1970s-1980s. Made by Puma Medici, it has some interesting features. The blade features a classic stiletto shape with a single factory-sharpened edge. It has a nail nick, which may reflect an expectation of a weak spring in the future. Or perhaps it simply means these blades were available from another project and used. The blade is stamped rostfrei and is most likely 440C steel. The spring is a double, side-by-side leaf spring and doesn't appear to be easy to replace. I typically store this knife open to prevent spring fatigue.

|

| Pro-Tech SBR |

My Pro-Tech is more of an art knife than a user. It's their SBR pattern with a "…unique micarta top, variety of colors, blade treatments, and inlay buttons." SBR stands for Short Bladed Rockeye, and the designer is Les George. The release button is inlaid with mother-of-pearl. There's no safety, but the button sits in an indent, so the top of the button is flush with the handle.

|

| Microtech's 2021 Blade Show knife |

I have a Microtech from the 2021

Blade Show. It's an OTF with a

double-edged dagger blade. The 3.3-inch

blade is ground from M390. M390 is

another great stainless steel, enriched with chromium, vanadium, and a touch of

tungsten. Double-edge knives have the

advantage of having two edges that can be sharpened. That is also a significant drawback in a

working knife. You can't use your other

hand to apply additional pressure to the back of the knife. At least not more than once. The other flaw is OTFs are famous for pulling

stuff back into the mechanism, creating problems. It's not hard to disassemble the knife, clean

it, and carefully lubricate it before reassembling. The lubrication tends to hold on to the crud

the blade pulls in. Again, not a major problem,

except that you need a small, special socket with a triangular opening to

disassemble this Microtech.

|

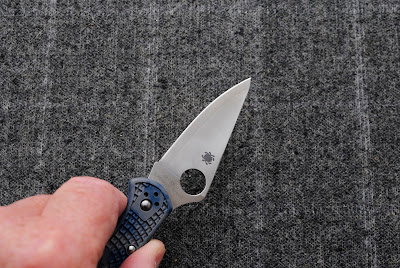

| Spyderco's Autonomy 2 |

Last on my list of possibilities is Spyderco's Autonomy 2. It's an auto knife made at the request of the US Navy for their rescue swimmers. Its wide, leaf-shaped blade is made from LC200N. This is an extremely rust-resistant steel. It has good toughness and edge retention. The release button is a large ring for gloved users. The safety is just beneath the release and has well-defined edges to grab gloves. I like the arrangement of safety and release. My thumb can operate the safety and release without having to change my grip. It's a nice knife, and at one time, only the overruns to military contracts were available to the public. Sal has well-defined ideas about how and who should use his knives.

So, which knife did I tell the Genie to bind me to?

|

| Behind the metal cap is Autonomy's spring. Easy to get to. Easy to oil. Easy to clean. |

The Spyderco Autonomy 2, of course. It's a well-made knife, and more importantly, if you turn it over, you'll find a metal cap with four holes in it. Under that cap is the knife's coil spring. Water drains from that spring cavity; you can oil the spring from there, and you simply unscrew the cap to replace the spring if needed.

Now, if the Genie's binding was

different, that I could only have one knife, I'd…

However, that's a story for

another day.