Last year at the

Blade Show, I noticed the Corgi Trek at Vosteed Knife. I was struck by the size, shape, and

interesting opening mechanism.

First, a little

about Vosteed Knife. Vosteed was started

in 2021 by Johnny and Yue Dong. The

plant is located in China. They work

with several international designers like Geoff Blauvelt and Ray Laconico, to name

a few. The mission statement declares,

“Honesty is a core business value.” I

have always found the best knife companies have simple, understandable

statements about fundamental values.

Yue Dong is the

in-house designer responsible for the Teck Lock on Corgi knives.

I like Vosteed

Knife. I spent more than a bit of money

at their booth at 2024 Blade.

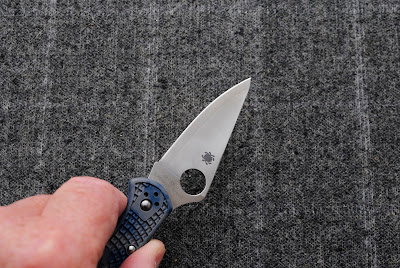

This Corgi has a

sheepsfoot blade with a high shoulder grind and reverse tanto point. The complex angles where the tanto meets the

spine give the blade an eye-candy look.

The sub-three-inch

blade is made from 14C28N steel hardened to a RHc of 60. This steel has been a favorite compared to S30V,

VG-10, and AEB-L, all quality knife steels.

Let's briefly look at the chemistry.

14C28N steel can vary depending on the manufacturer, but it generally

contains:

14% Chromium:

Provides corrosion resistance and hardness,

0.6% Carbon:

Increases hardness and wear resistance,

0.3% Nitrogen:

Improves hardness and corrosion resistance,

0.3% Manganese:

Improves hardenability and wear resistance,

and trace

amounts of Silicon, Phosphorus, and Sulfur.

The last three improve machinability.

14C28N steel has

excellent edge retention and improved hardness due to the nitrogen content. More than one reviewer thinks it's a great

choice for tasks that require a sharp edge, like cutting and slicing.

The levels of

chromium provide good resistance to rust resistance and other forms of

corrosion. I have a knife that I

accidentally ‘patinaed’ by slicing lemons.

Don’t laugh, it could happen to you.

|

| the reversible clip |

The blade is

housed in a reinforced frame with a blue-gray micarta handle. The knife comes with a deep carry clip for

right-side, tip-up carry. The clip is

reversible. You can't help but notice

the depression that takes the clips has a metal plug filling it. It gives the knife a look of

completeness. It's something you don't

see on many higher-end knives.

|

| Opening flippers |

The knife opener

is called “front and back flippers."

The flippers have a bit of gimping for friction, and you open the knife

by pressing down on the ear. The blade

glides open on caged ceramic ball bearings.

This is high-tech stuff.

|

| A little pressure on the opening tab and the Corgi flies open |

Ceramic ball

bearings have high hardness and elastic modulus. No, that's not techno-babble; it means the

bearings resist deformation under load and have increased wear and corrosion

resistance. They can run

lubricant-free. If you must rinse the

knife out and can't re-oil it, the bearings have your back.

There is a

downside. Ceramic bearings are sensitive

to thermal shock and have lower load capacities. These aren't really problems for knives.

Time for a true

confession. I don't sell knives from my

blog, and I don't own this Corgi. I know

it feels good in my hand, but I’m not about to use someone else's knife in

cutting tests. On the Vosteed website, I

noticed that their current stock was low.

What will the proposed trade tariffs affect? I don't know.

If you're

looking for one, I'd act sooner than later.