My father used to carve wooden

knives, mostly daggers. He’d start with

a square rod of scrap pine and carve a handle with grooves, holes, partial

spheres and a V-shaped edge he called a blade.

It was just a way for him and me to whittle away an hour. I’m sure I was better at making shavings than

anything resembling a knife.

But I never forgot carved wooden

knives.

At the Lehigh Valley Knife Show I

ran into Dean the owner of “The Last Table” who is making wooden knives. Specifically folding

lock back knives.

|

| Here's the details, you just need to add skill and years of practice. |

Following his retirement three

years ago, Dean has been a serious work worker producing furniture you want to

own. He showed me a logo he first carved

into a dry bar for a customer and then took it up a notch by flaming it with

gunpowder. Talk about “Edgy”!

Last year Dean gave some thought

to wooden knives and started experimenting.

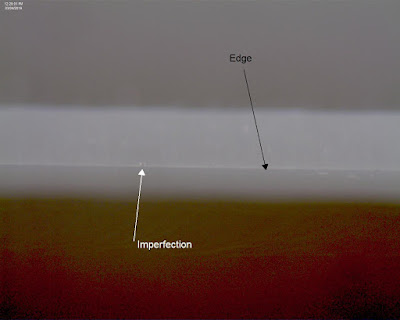

When you open his folders the lock, driven by a wooden spring, clicks

into place locking the knife open.

|

| Is this cool or not? It is!! |

The

spine lock is depressed against the same wood spring to unlock the knife and

the blade snaps tightly into the bolsters.

It sounds like a Buck 110 opening and closing.

There is no metal used in the

knife, just wood and wooden pins. I got

a really nice one made of burly maple that I think is super.

|

| The selection of interesting woods is amazing The top marble wood is very interesting as is the second osage orange. |

We were talking and Dean showed

me an experimental wood Ka-Bar style knife he had made. The handle is composed of two different woods

and the blade is stained dark. Look at

the handle butt and you can see the partial tang a classic Ka-Bar has.

|

| One of the few Ka-Bars that can float in water, but it's too nice to do that.! |

Dean’s working on a website, but

it’s not quite there. It will be OH

Wooden Lock-back Knives. The OH stands

for Open Heart and not Ohio. Trust me. You can see the heart he puts into these

knives. The name works.

I told Dean I thought mixing

different woods for blades and bolsters would be attractive. I can

see even different woods stacked to form the bolsters. Of course, it’s easy for me to make

suggestions when I don’t have to execute the design.

I understand a Floridian has made

a large purchase and I suspect we’ll see these at the upcoming Blade Show. I’ll be looking for them.

You can contact Dean at deangiesige@icloud.com if you’re

interested in having custom work done. I

recognize quality wood work when I see it.

This is the real thing!

https://www.facebook.com/thelasttable1/who